Warehouse Temperature and Humidity Monitoring: Ensuring Optimal Conditions

Introduction to Warehouse Temperature and Humidity Monitoring

In the world of logistics and storage, maintaining the right environmental conditions in a warehouse is paramount. Temperature and humidity control are not just about comfort; they are critical for preserving the integrity of stored goods. Whether dealing with perishable food items, pharmaceuticals, or sensitive electronics, improper temperature and humidity levels can lead to spoilage, degradation, and significant financial loss. This article delves into the importance of monitoring these environmental factors and explores how technology can aid in maintaining optimal warehouse conditions.

The Importance of Temperature Monitoring

Temperature control in warehouses is vital for several reasons. Firstly, it ensures the quality and safety of temperature-sensitive products, such as food and pharmaceuticals. These items require specific temperature ranges to prevent spoilage and maintain efficacy. For instance, vaccines must be stored within a narrow temperature range to remain effective. Moreover, temperature fluctuations can lead to condensation, which might damage packaging and labels, leading to further complications in product handling.

Effective temperature monitoring involves the use of sensors and automated systems that provide real-time data and alerts. This technology allows warehouse managers to respond promptly to any deviations, ensuring that products remain within their required temperature thresholds. Furthermore, maintaining consistent temperatures can also contribute to energy efficiency, as it prevents the overuse of heating or cooling systems.

The Role of Humidity Control

Humidity control is equally important in warehouse environments. High humidity levels can lead to mold growth, corrosion, and deterioration of products, particularly those made of paper, textiles, or metal. Conversely, low humidity can cause materials like wood and paper to become brittle and prone to damage. Therefore, maintaining an optimal humidity level is crucial for preserving the quality of stored goods.

Advanced humidity monitoring systems can detect changes in moisture levels and trigger dehumidifiers or humidifiers as needed. These systems often integrate with temperature controls to provide a comprehensive environmental management solution. By maintaining the right humidity levels, warehouses can prevent product damage and extend the shelf life of their inventory.

Technology Solutions for Monitoring

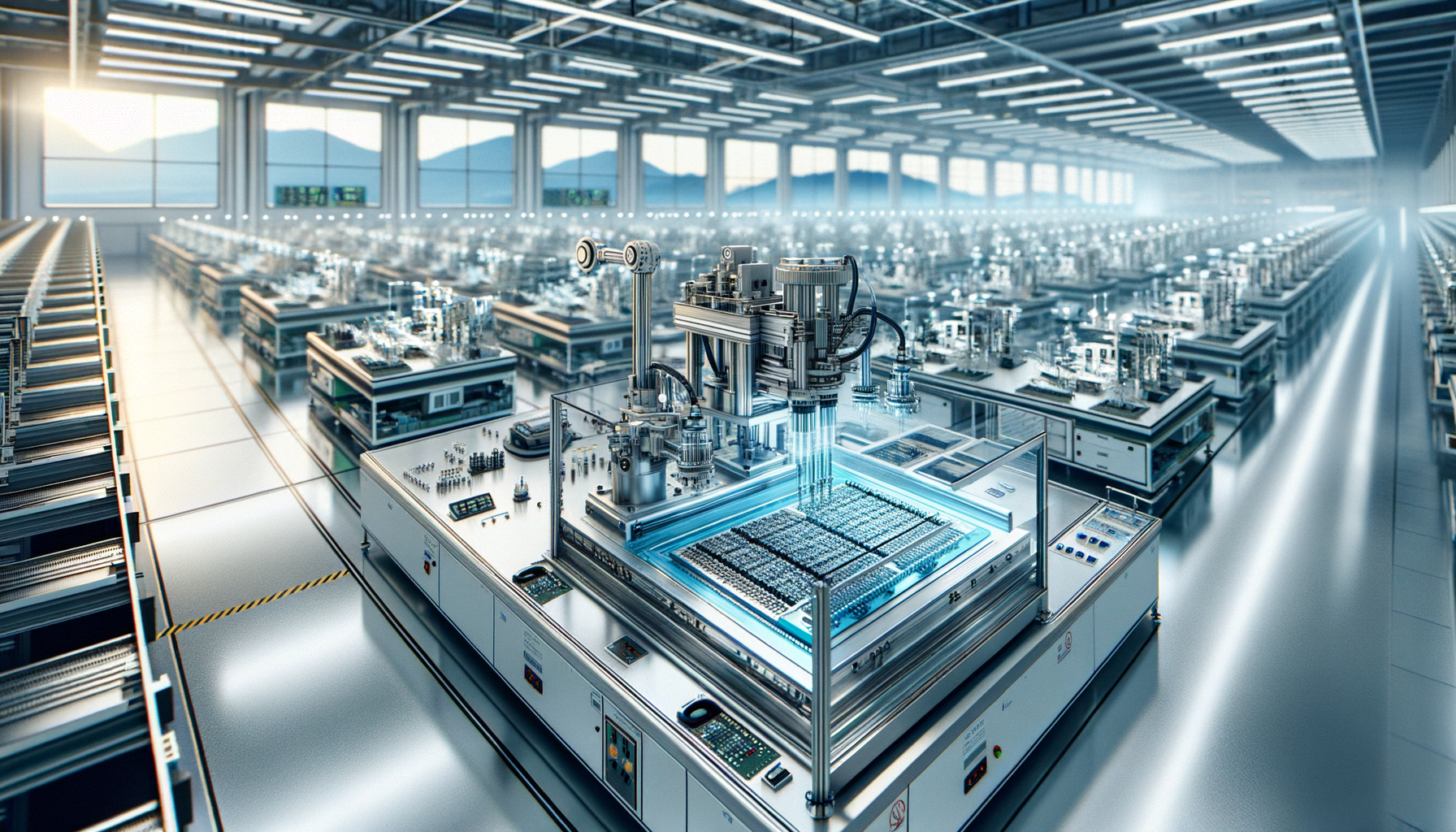

Modern technology offers a range of solutions for effective temperature and humidity monitoring in warehouses. Wireless sensors, for example, can be placed throughout a facility to provide continuous data on environmental conditions. These sensors can transmit information to a central system, where it can be analyzed and used to make informed decisions about climate control.

Additionally, IoT (Internet of Things) devices can automate the monitoring process, providing alerts and even adjusting environmental controls automatically. This level of automation not only ensures consistent conditions but also reduces the need for manual checks, saving time and labor costs. Moreover, data collected over time can be used for predictive analysis, helping warehouse managers anticipate potential issues before they arise.

Challenges and Considerations

Despite the advantages of temperature and humidity monitoring, there are challenges to consider. Implementing a comprehensive monitoring system requires an initial investment in technology and infrastructure. Additionally, staff must be trained to use these systems effectively, which can involve a learning curve.

Another consideration is the integration of monitoring systems with existing warehouse management systems. Compatibility issues can arise, necessitating careful planning and possibly custom solutions. However, the long-term benefits of reduced product loss and improved operational efficiency often outweigh these initial challenges.

Ultimately, the successful implementation of temperature and humidity monitoring systems hinges on selecting the right technology and ensuring that all stakeholders understand its importance. By doing so, warehouses can protect their inventory, improve operational efficiency, and enhance customer satisfaction.

Conclusion: The Future of Warehouse Monitoring

As technology continues to advance, the future of warehouse temperature and humidity monitoring looks promising. Innovations such as AI and machine learning are poised to bring even greater precision and efficiency to environmental management systems. These technologies could lead to more proactive approaches, where systems predict and adjust conditions based on historical data and trends.

For warehouse operators, investing in temperature and humidity monitoring is not just about compliance or avoiding losses; it’s about optimizing the entire supply chain. By maintaining optimal conditions, warehouses can ensure the quality and longevity of their products, reduce waste, and ultimately, improve their bottom line. As such, embracing these technologies is a strategic move towards a more sustainable and efficient future.