Understanding the Chilltech Heat Exchanger: Efficiency and Applications

Introduction to Heat Exchangers

Heat exchangers are crucial components in many industrial processes, facilitating the transfer of heat between two or more fluids. They play a vital role in energy conservation and efficiency across various sectors, including power generation, chemical processing, and HVAC systems. The Chilltech Heat Exchanger, in particular, stands out for its innovative design and application versatility, making it a preferred choice for many engineers and facility managers.

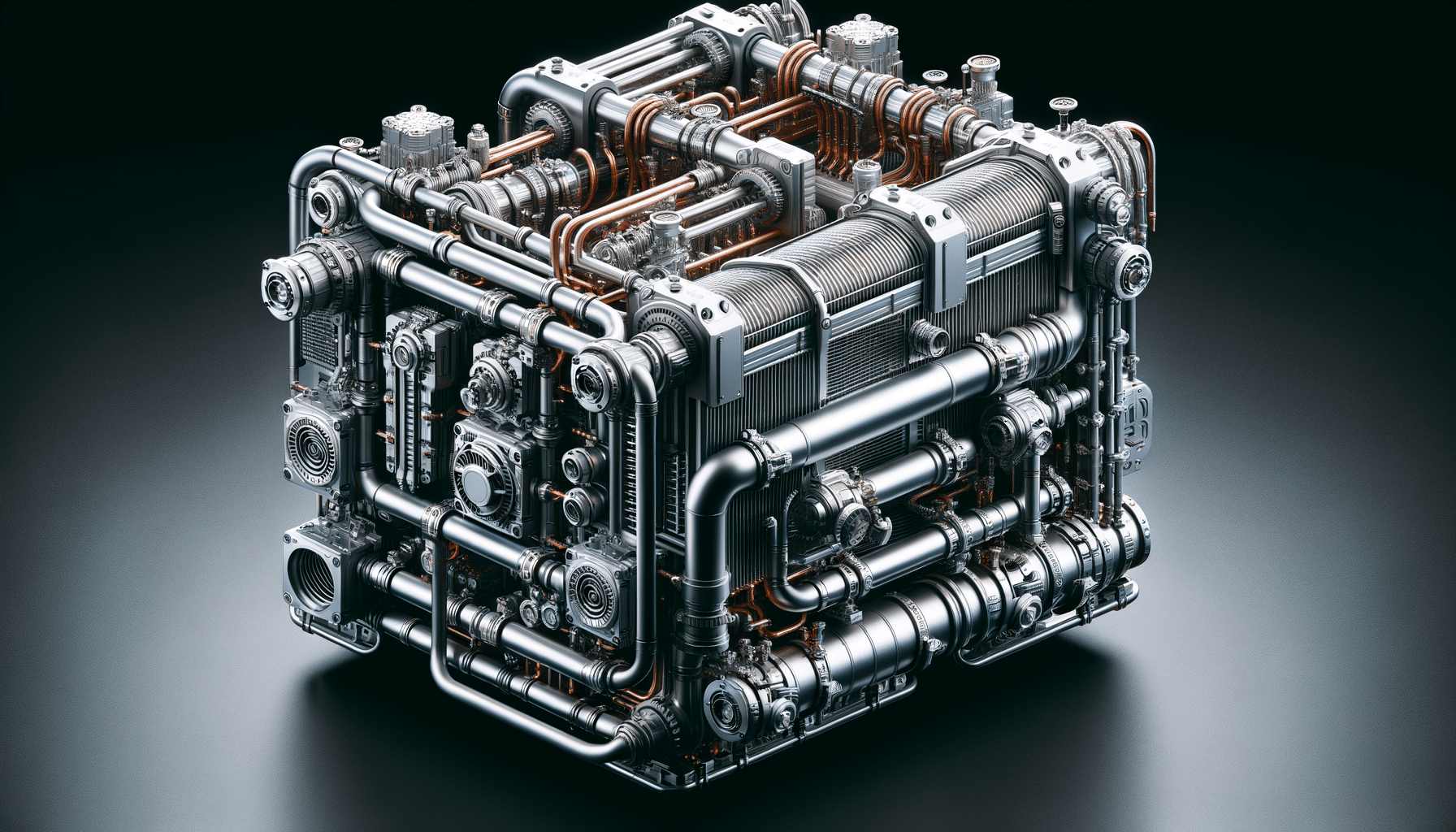

Design and Functionality of Chilltech Heat Exchanger

The Chilltech Heat Exchanger is designed with efficiency and durability in mind. Its core function is to transfer heat from one medium to another without mixing the two. This is achieved through a series of plates or tubes that separate the fluids while allowing heat to pass through. The design is compact, which is advantageous for installations where space is limited. Additionally, the materials used in its construction are chosen to withstand high pressure and temperature conditions, ensuring long-term reliability.

Applications in Various Industries

The versatility of the Chilltech Heat Exchanger makes it suitable for a wide range of applications. In the chemical industry, it is used to control reaction temperatures, thereby improving safety and efficiency. In HVAC systems, it enhances energy efficiency by recovering waste heat. Furthermore, in power plants, it aids in the efficient conversion of thermal energy into electricity. This adaptability across industries underscores its importance in modern engineering solutions.

Benefits of Using Chilltech Heat Exchangers

There are several benefits to using Chilltech Heat Exchangers. Firstly, they contribute to energy savings by maximizing heat recovery and reducing the overall energy consumption of a system. Secondly, their robust design minimizes maintenance requirements and downtime, leading to cost savings over time. Thirdly, their adaptability to different fluids and temperatures makes them a flexible solution for various industrial needs. These benefits collectively enhance operational efficiency and sustainability.

Conclusion and Future Prospects

In conclusion, the Chilltech Heat Exchanger is a pivotal component in enhancing the efficiency and sustainability of industrial processes. Its design and functionality cater to a broad spectrum of applications, making it a valuable asset in energy management. As industries continue to seek more sustainable and efficient solutions, the role of heat exchangers like those offered by Chilltech will undoubtedly grow. Investing in such technology not only meets current demands but also prepares industries for future challenges in energy conservation and efficiency.