Understanding Data Loggers for Cold Storage: Ensuring Optimal Temperature Control

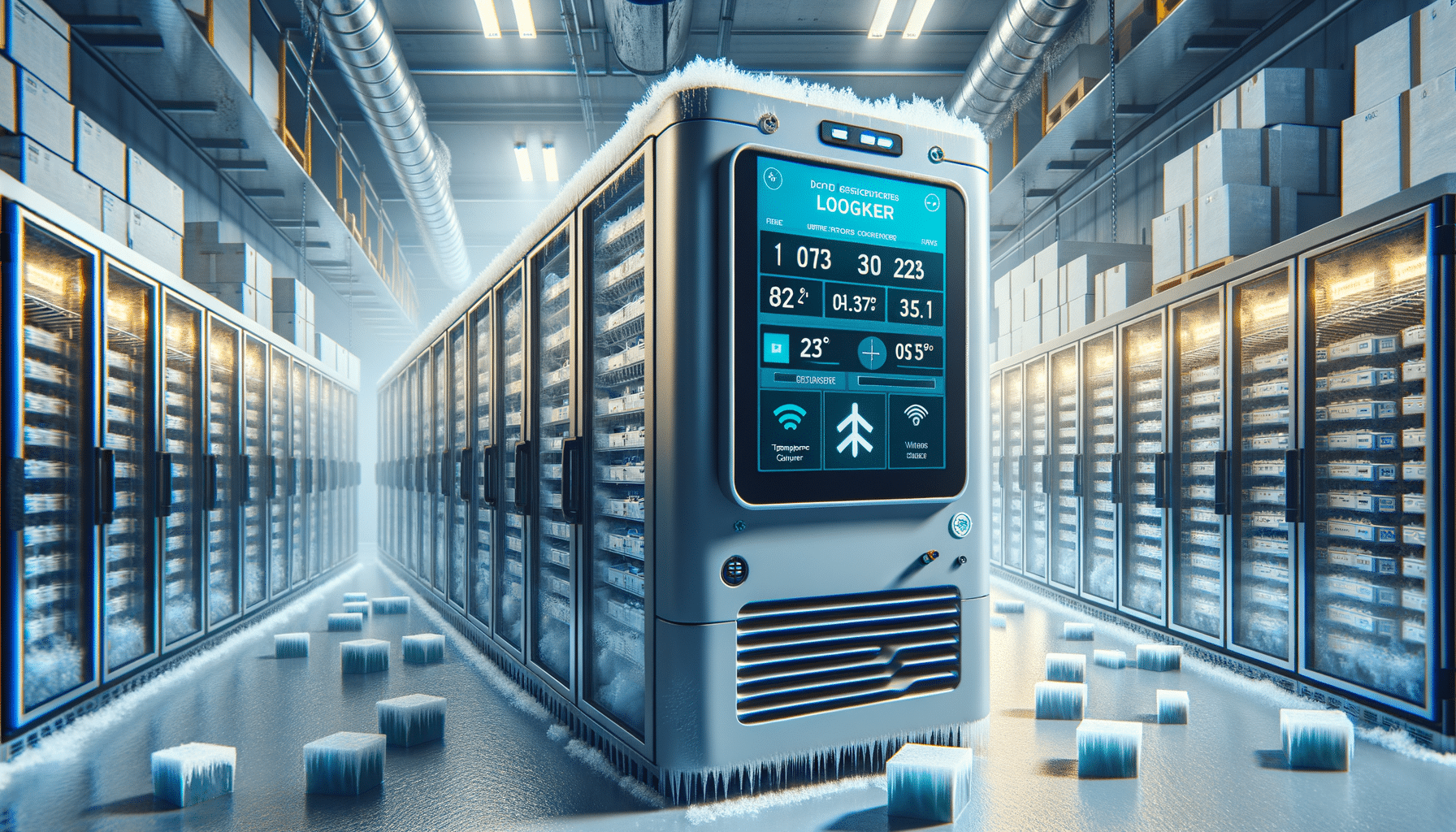

Introduction to Data Loggers for Cold Storage

In the realm of cold storage, maintaining precise temperature control is crucial for preserving the integrity of stored goods. This is where data loggers come into play. These devices are designed to continuously monitor and record temperature data, ensuring that storage conditions remain within specified parameters. With the increasing demand for temperature-sensitive products, the role of data loggers has become more significant than ever. They provide a reliable means of tracking environmental conditions, helping businesses comply with regulatory standards and maintain product quality.

How Data Loggers Work

Data loggers are equipped with sensors that measure environmental parameters such as temperature and humidity. These sensors collect data at regular intervals, which is then stored in the device’s memory. The stored data can be retrieved and analyzed to ensure that the storage environment remains within the desired range. Most data loggers offer features like real-time monitoring, alarms for out-of-range conditions, and data export capabilities. These features make them invaluable tools for industries that require precise environmental control, such as pharmaceuticals, food and beverage, and logistics.

Some key features of data loggers include:

- High accuracy and precision in temperature measurement

- Long battery life for extended monitoring periods

- Wireless connectivity options for remote data access

- Robust construction to withstand harsh environments

Applications of Data Loggers in Various Industries

Data loggers are used across multiple industries to ensure that products are stored under optimal conditions. In the pharmaceutical industry, for example, maintaining the correct temperature is crucial for the efficacy of vaccines and medications. Data loggers provide a reliable means of ensuring that these products are stored within the required temperature range. Similarly, in the food and beverage industry, data loggers help prevent spoilage by monitoring the temperature of perishable goods.

Other industries that benefit from data loggers include:

- Agriculture: Monitoring soil and environmental conditions

- Logistics: Ensuring the integrity of temperature-sensitive shipments

- Research: Recording environmental data for scientific studies

Choosing the Right Data Logger for Your Needs

Selecting the appropriate data logger depends on several factors, including the specific requirements of your industry and the environmental conditions of your storage facility. Considerations include the range and accuracy of the temperature sensor, the data storage capacity, and the ease of data retrieval. It’s also important to consider whether the data logger offers features such as wireless connectivity and alarm notifications.

When evaluating data loggers, consider the following:

- The type of sensor required (e.g., thermocouple, RTD)

- Data access options (e.g., USB, Bluetooth, cloud-based)

- Durability and resistance to environmental factors

- Cost and overall value for your specific application

Conclusion: Ensuring Optimal Storage Conditions with Data Loggers

Data loggers are indispensable tools for maintaining optimal conditions in cold storage environments. By providing accurate and continuous monitoring, they help businesses ensure product quality and compliance with industry standards. As the demand for temperature-sensitive products continues to grow, the importance of data loggers in safeguarding product integrity cannot be overstated. Whether you are in the pharmaceutical, food, or logistics industry, investing in a reliable data logger can provide peace of mind and protect your valuable assets.