Understanding Core Cutting Machine Prices: A Comprehensive Guide

Introduction to Core Cutting Machines

Core cutting machines are essential tools in construction and industrial sectors, used for precise cutting of concrete, masonry, and other hard materials. These machines are invaluable for creating openings for pipes, wires, and other installations in a variety of structures. Understanding the pricing of core cutting machines is crucial for businesses and individuals planning to invest in this equipment. In this article, we delve into the factors affecting core cutting machine prices and provide insights to help you make informed purchasing decisions.

Factors Influencing Core Cutting Machine Prices

Several factors contribute to the cost of core cutting machines. First, the type of machine significantly impacts the price. Machines designed for heavy-duty industrial use generally cost more than those intended for lighter, occasional use. Additionally, the size and capacity of the machine play a role in pricing, with larger and more powerful machines commanding higher prices.

Another critical factor is the technology and features incorporated into the machine. Advanced features such as automated operation, enhanced safety mechanisms, and precision controls can increase the cost. Brand reputation also influences pricing, as machines from well-regarded manufacturers often come with a premium due to their reliability and customer support.

Lastly, market demand and supply dynamics can affect prices. During periods of high construction activity, demand for core cutting machines may rise, leading to increased prices. Conversely, during economic downturns, prices may decrease as demand wanes.

Comparing Different Types of Core Cutting Machines

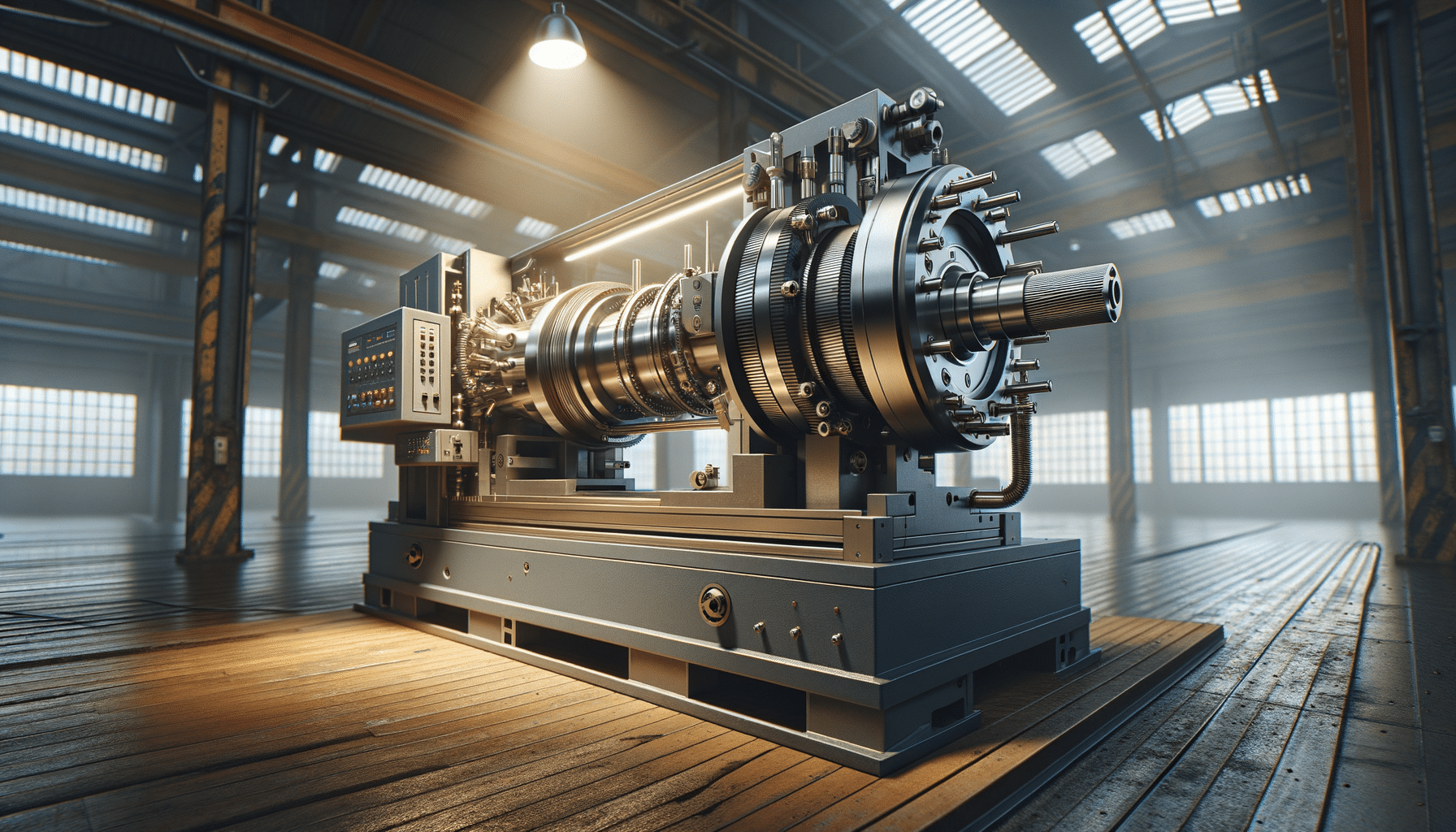

Core cutting machines come in various types, each suited to specific tasks and environments. Hand-held core cutting machines are portable and ideal for small-scale jobs or confined spaces. These machines are generally more affordable, making them a popular choice for smaller businesses or DIY enthusiasts.

On the other hand, rig-mounted core cutting machines are designed for larger projects and offer greater stability and precision. These machines are more expensive but provide superior performance for heavy-duty tasks. Hydraulic core cutting machines are another option, offering powerful cutting capabilities and efficiency in demanding conditions. However, their advanced technology and robust design contribute to higher costs.

When choosing a core cutting machine, it’s essential to consider the specific needs of your project and balance them against your budget to find the most suitable option.

Tips for Purchasing a Core Cutting Machine

When purchasing a core cutting machine, it’s important to conduct thorough research to ensure you select the right equipment for your needs. Start by identifying the specific requirements of your projects, such as the types of materials you’ll be cutting and the frequency of use. This will help you determine the appropriate type and size of the machine.

Next, compare prices from different suppliers and consider both new and used options. While new machines offer the latest technology and warranty coverage, used machines can provide significant cost savings. However, ensure that used machines are in good condition and have been well-maintained.

Additionally, consider the availability of spare parts and after-sales support. Machines from renowned manufacturers may have a higher initial cost but can offer better long-term value through reliable support and readily available parts.

Conclusion: Making an Informed Decision

Investing in a core cutting machine requires careful consideration of various factors, including the type of machine, its features, and the specific needs of your projects. By understanding the factors influencing core cutting machine prices, you can make informed decisions that balance performance with budget constraints.

Ultimately, the goal is to select a machine that meets your operational requirements while offering reliability and efficiency. Whether you opt for a compact hand-held model or a powerful rig-mounted machine, ensuring it aligns with your project’s demands will lead to successful outcomes and a worthwhile investment.