Heavy Earth Moving Machinery in Mining

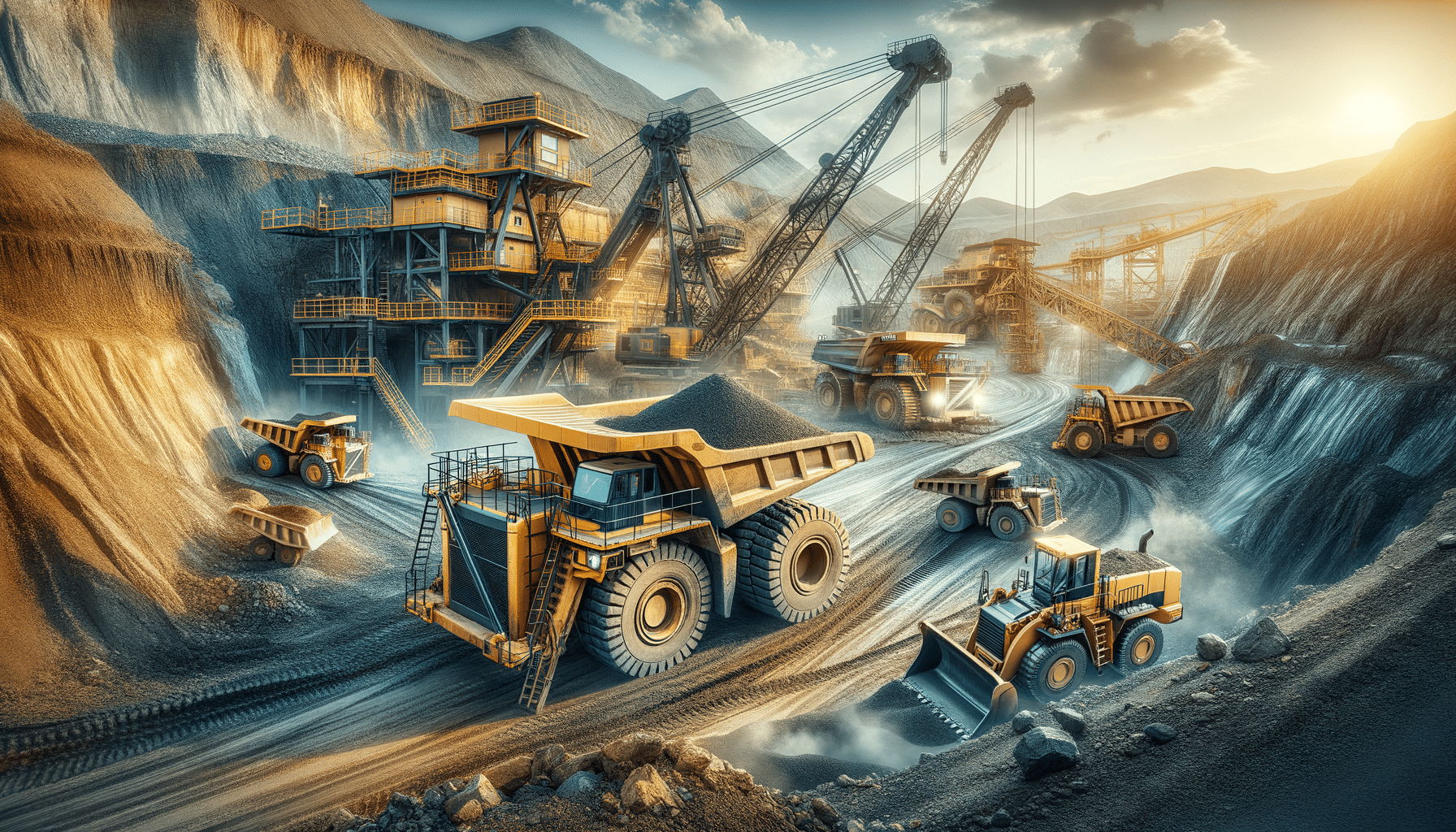

Introduction to Heavy Earth Moving Machinery in Mining

Mining is an industry that has been at the heart of human civilization for centuries, providing essential resources that fuel technological advancements and economic growth. At the core of modern mining operations are heavy earth moving machinery, which play a crucial role in the extraction of minerals and ores from the earth. These machines are not only vital for efficiency and productivity but also for ensuring the safety and sustainability of mining practices.

In this article, we will delve into the various types of heavy machinery used in mining, their functions, and how they contribute to the overall mining process. We will also explore the technological advancements that have transformed these machines into highly efficient tools, capable of operating in the most challenging environments.

Types of Heavy Earth Moving Machinery

Heavy earth moving machinery in mining encompasses a wide range of equipment, each designed for specific tasks and environments. Some of the most commonly used machines include:

- Excavators: These versatile machines are used for digging and removing overburden, which is the layer of soil and rock covering the mineral deposits. Excavators come in various sizes and configurations, allowing them to adapt to different mining conditions.

- Bulldozers: Known for their strength and durability, bulldozers are used to clear and level large areas of land. They are essential for preparing mining sites and maintaining haul roads.

- Dump Trucks: These large vehicles are used to transport extracted material from the mining site to processing facilities. They are designed to handle heavy loads and operate efficiently in rugged terrain.

- Loaders: Loaders are used to scoop and transport materials within the mining site. They are crucial for loading trucks and feeding processing equipment.

- Drills: Drills are used to create holes for explosives, which are then used to break apart rock formations. This process is essential for accessing underground mineral deposits.

Each of these machines plays a specific role in the mining process, working together to ensure the efficient extraction and transportation of materials.

The Role of Technology in Enhancing Machinery Efficiency

Technological advancements have significantly enhanced the efficiency and capabilities of heavy earth moving machinery in mining. Modern machines are equipped with advanced features such as GPS systems, automated controls, and real-time monitoring, which improve precision and reduce operational costs.

For instance, GPS technology allows for precise navigation and positioning of machinery, ensuring that excavation and loading are conducted with minimal waste. Automated controls enable machines to operate with minimal human intervention, reducing the risk of accidents and improving productivity.

Real-time monitoring systems provide operators with critical data on machine performance, fuel consumption, and maintenance needs. This information allows for proactive maintenance and reduces downtime, ensuring that machinery operates at peak efficiency.

Moreover, the integration of artificial intelligence and machine learning is paving the way for fully autonomous mining operations. These technologies enable machines to learn from their environment and optimize their performance, further enhancing the safety and efficiency of mining activities.

Environmental and Safety Considerations

While heavy earth moving machinery is essential for mining operations, it also poses environmental and safety challenges. The extraction and transportation of minerals can lead to habitat destruction, soil erosion, and pollution. Therefore, it is crucial for mining companies to implement sustainable practices and minimize their environmental impact.

Many modern machines are designed with eco-friendly features, such as low-emission engines and energy-efficient systems, to reduce their carbon footprint. Additionally, companies are adopting practices such as land reclamation and waste management to restore mined areas and mitigate environmental damage.

Safety is another critical consideration in mining operations. Heavy machinery can pose significant risks to operators and workers if not properly managed. To address this, mining companies invest in comprehensive training programs and safety protocols to ensure that machinery is operated safely and efficiently.

Advanced safety features, such as collision avoidance systems and remote monitoring, further enhance the safety of mining operations, protecting both workers and equipment.

Future Trends in Mining Machinery

The future of heavy earth moving machinery in mining is set to be shaped by continued technological innovation and a growing emphasis on sustainability. As the demand for minerals and resources increases, mining companies are exploring new ways to enhance the efficiency and environmental performance of their operations.

One promising trend is the development of electric and hybrid machinery, which offers the potential to significantly reduce emissions and fuel consumption. These machines are designed to operate with minimal environmental impact, aligning with global efforts to combat climate change.

Additionally, the use of data analytics and the Internet of Things (IoT) is transforming how mining companies manage their operations. By collecting and analyzing vast amounts of data, companies can optimize machinery performance, improve decision-making, and reduce operational costs.

As these trends continue to evolve, heavy earth moving machinery will play a pivotal role in shaping the future of mining, driving progress towards more efficient, sustainable, and safe operations.