Exploring Tungsten Carbide Tips Manufacturers in Europe

Introduction to Tungsten Carbide Tips

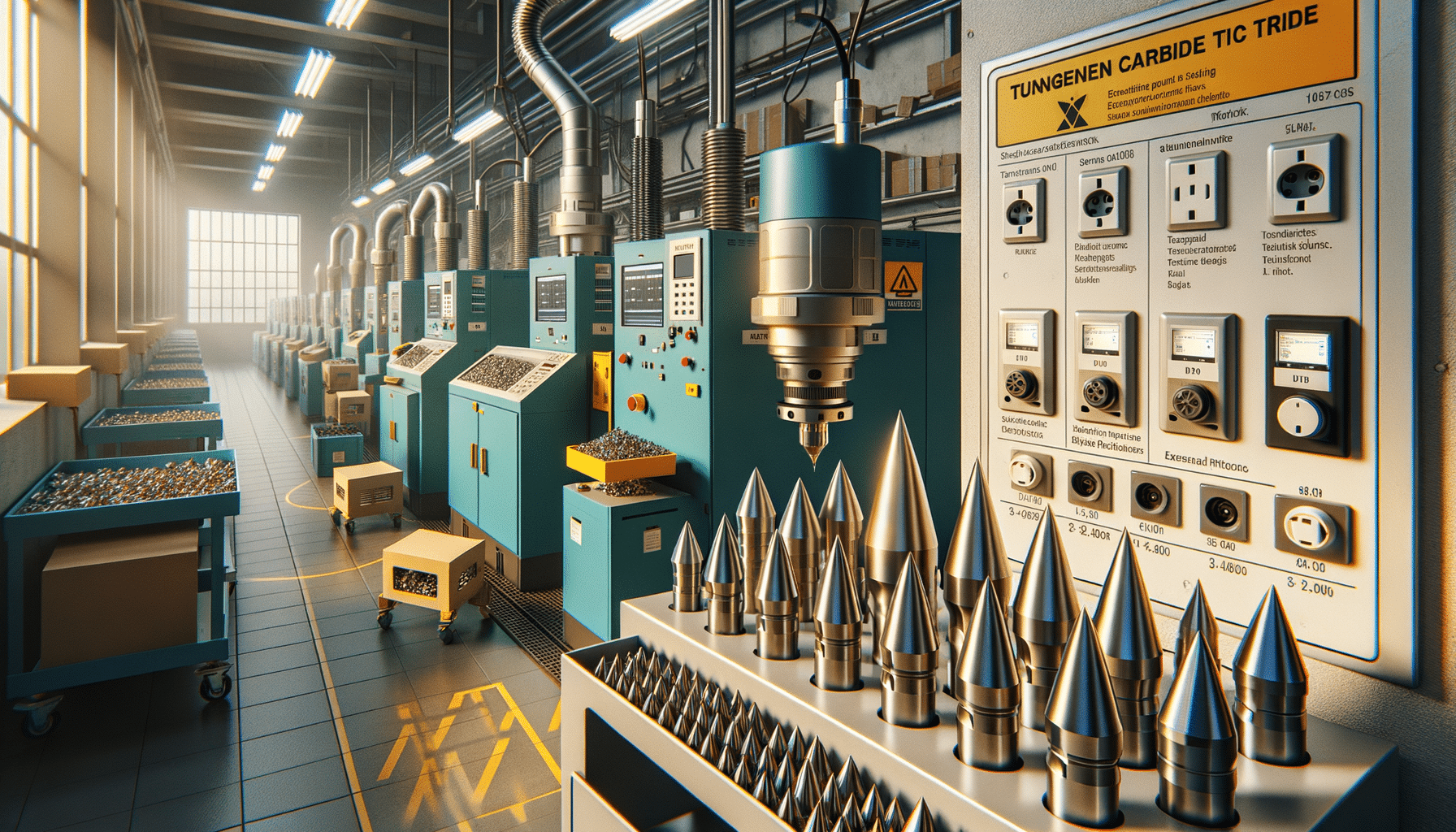

Tungsten carbide tips are renowned for their strength and durability, making them indispensable in industries such as mining, construction, and manufacturing. These tips are crafted by combining tungsten and carbon atoms, resulting in a compound that is nearly as hard as diamond. In Europe, manufacturers of tungsten carbide tips are recognized for their high standards and innovative techniques, providing essential components for cutting tools, drilling bits, and wear-resistant applications. Understanding the landscape of tungsten carbide tips manufacturers in Europe is crucial for businesses seeking reliable and high-quality products.

Leading Manufacturers in Europe

Europe hosts several prominent manufacturers of tungsten carbide tips, each bringing unique strengths to the industry. These companies are known for their advanced production technologies and adherence to rigorous quality standards. Some of the key players include:

- Germany: Known for its precision engineering, Germany is home to manufacturers that excel in producing carbide tools with exceptional accuracy and longevity.

- Italy: Italian manufacturers are celebrated for their innovative designs and commitment to sustainability in the production process.

- France: With a focus on research and development, French companies often lead in creating new carbide formulations to enhance performance.

These manufacturers not only supply to local markets but also export globally, reinforcing Europe’s position as a leader in tungsten carbide production.

Applications of Tungsten Carbide Tips

Tungsten carbide tips are utilized across various sectors due to their remarkable properties. In the construction industry, they are used in tools for cutting and drilling through tough materials like concrete and steel. In the mining sector, their durability makes them ideal for heavy-duty drilling operations. Additionally, tungsten carbide tips are employed in manufacturing processes for shaping and forming metals, ensuring precision and efficiency.

These applications highlight the versatility and essential nature of tungsten carbide tips, driving demand for high-quality production from European manufacturers.

Quality Standards and Certifications

European manufacturers of tungsten carbide tips adhere to stringent quality standards to ensure their products meet the demands of various industries. Many companies are certified under international standards such as ISO 9001, which ensures consistent quality management practices. Additionally, environmental certifications like ISO 14001 are becoming increasingly important, reflecting the industry’s commitment to sustainable manufacturing processes.

These certifications not only assure customers of the product’s reliability but also demonstrate the manufacturers’ dedication to responsible production practices.

Future Trends and Innovations

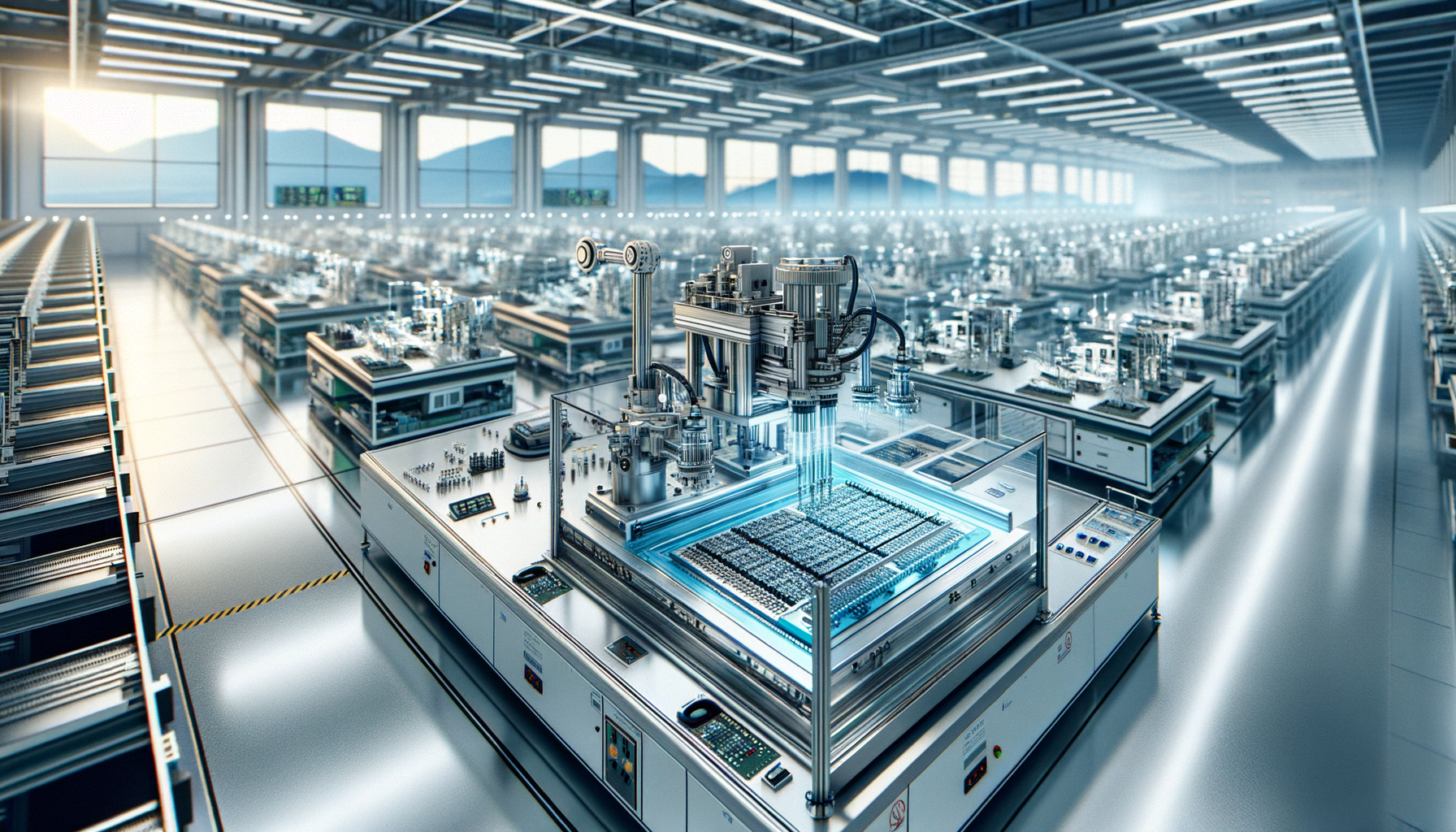

The future of tungsten carbide tips manufacturing in Europe is poised for exciting developments. Innovations in materials science are leading to the creation of even more durable and efficient carbide products. Furthermore, the integration of smart technologies in manufacturing processes is enhancing precision and reducing waste.

As industries continue to evolve, the demand for high-performance tools is expected to grow, driving manufacturers to explore new techniques and materials. This ongoing innovation ensures that European manufacturers remain at the forefront of the global tungsten carbide industry.