Exploring the Applications of Air Cooled Chillers

Introduction to Air Cooled Chillers

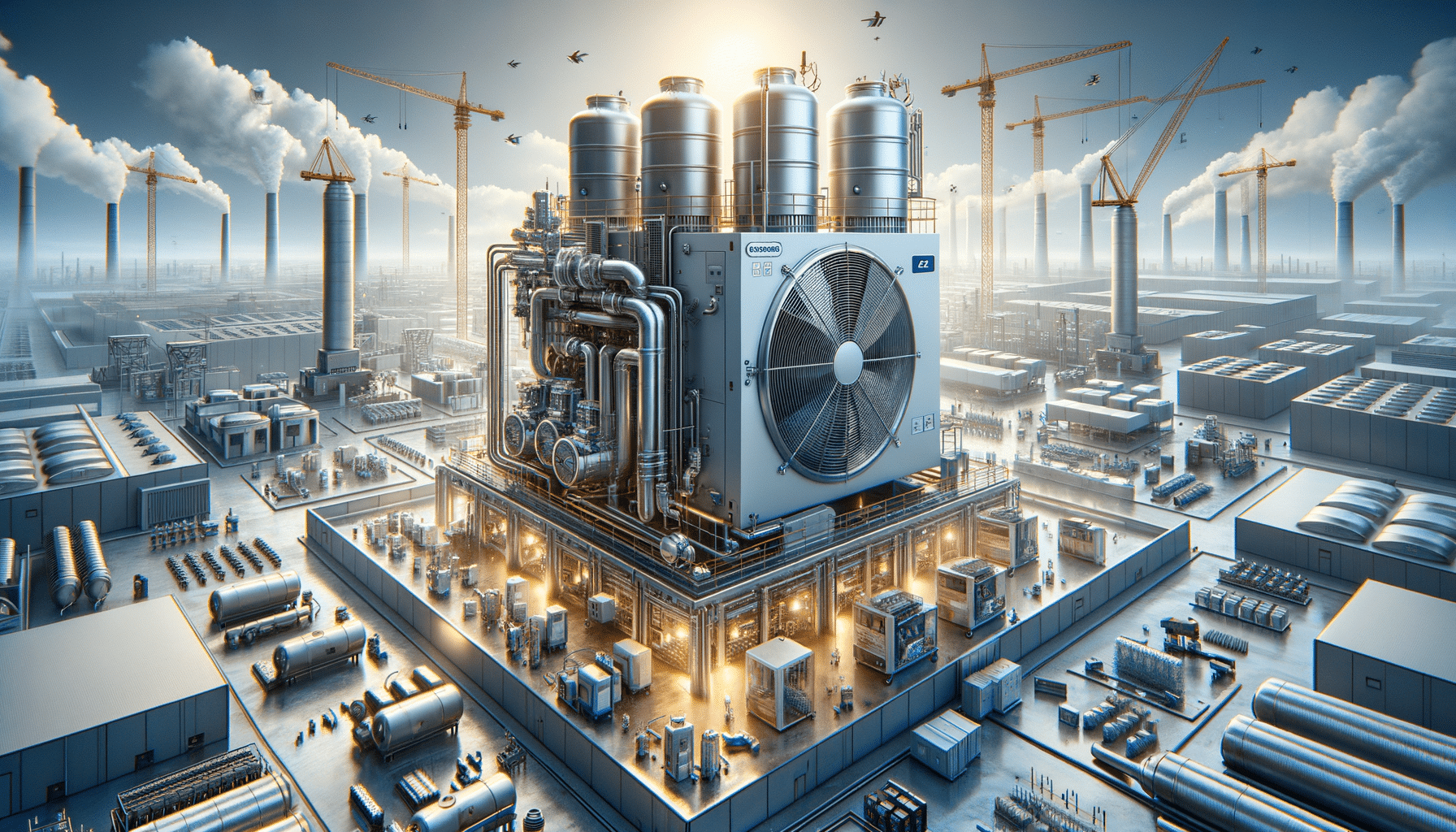

Air cooled chillers are a crucial part of many industrial and commercial settings, providing efficient cooling solutions by using air to dissipate heat from the refrigerant. Unlike water-cooled systems that rely on water towers, air cooled chillers are more flexible and easier to install, making them a preferred choice in locations where water resources are limited or where water conservation is a priority. Their relevance extends to various sectors, including manufacturing, food and beverage, and healthcare, among others.

These systems are particularly advantageous in areas with lower humidity levels, as they can operate effectively without the need for additional water resources. As industries continue to grow, the demand for reliable and efficient cooling systems like air cooled chillers is expected to rise, highlighting their importance in modern infrastructure.

Key Features and Benefits of Air Cooled Chillers

Air cooled chillers offer numerous benefits that make them suitable for various applications. One of their main advantages is the ease of installation and maintenance. Since they do not require cooling towers, the initial setup is often less complex and more cost-effective. Additionally, their design allows for flexibility in placement, as they can be installed outdoors without the need for elaborate piping systems.

Another significant benefit is their energy efficiency. Modern air cooled chillers are designed to minimize energy consumption while maximizing cooling capacity. This makes them an environmentally friendly option, as they help reduce carbon footprints by lowering energy usage. Moreover, they are equipped with advanced control systems that allow for precise temperature regulation, ensuring optimal performance in different conditions.

Some of the key features include:

- Robust construction for durability in various environments

- Advanced control systems for efficient operation

- Low maintenance requirements due to fewer components

- Flexibility in installation locations

Applications in Different Industries

Air cooled chillers are utilized across a wide range of industries due to their versatility and efficiency. In the manufacturing sector, they are used to cool machinery and equipment, preventing overheating and ensuring smooth operations. This is particularly important in processes that generate a lot of heat, such as plastic molding and metalworking.

In the food and beverage industry, air cooled chillers play a critical role in maintaining the quality and safety of products. They are used to cool ingredients during processing and to keep storage areas at the appropriate temperatures. This helps in preserving the freshness of perishable goods and extending their shelf life.

Healthcare facilities also benefit from air cooled chillers, as they provide the necessary cooling for medical equipment and ensure a comfortable environment for patients and staff. In hospitals, maintaining precise temperatures is crucial for both patient care and the operation of sensitive medical devices.

Comparing Air Cooled and Water Cooled Chillers

When choosing between air cooled and water cooled chillers, it’s important to consider the specific needs and constraints of the application. Air cooled chillers are generally preferred in areas where water availability is a concern or where water conservation is prioritized. They are less complex to install and maintain, which can lead to cost savings in the long run.

On the other hand, water cooled chillers are often more efficient in terms of energy use, particularly in larger installations. They are capable of handling higher cooling loads and can be more effective in humid environments. However, they require a reliable water source and additional infrastructure such as cooling towers, which can increase both initial and operational costs.

Ultimately, the choice between air cooled and water cooled chillers depends on factors such as environmental conditions, installation location, and budget constraints. Each type offers unique advantages that can be leveraged to meet the specific cooling needs of different applications.

Future Trends and Innovations

The future of air cooled chillers looks promising, with ongoing innovations aimed at enhancing their efficiency and sustainability. As the demand for energy-efficient solutions grows, manufacturers are focusing on developing chillers that offer superior performance with reduced environmental impact.

One of the emerging trends is the integration of smart technologies into chiller systems. This includes the use of IoT devices and advanced analytics to monitor performance and optimize operations in real-time. Such innovations not only improve efficiency but also extend the lifespan of the equipment by enabling predictive maintenance and reducing downtime.

Another area of development is the use of eco-friendly refrigerants that have lower global warming potential compared to traditional options. This shift is driven by stringent environmental regulations and a growing commitment to sustainability across industries.

As these trends continue to evolve, air cooled chillers are expected to become even more integral to industrial and commercial cooling applications, offering reliable and sustainable solutions for the future.