Exploring Perforated Stainless Steel Sheet Suppliers

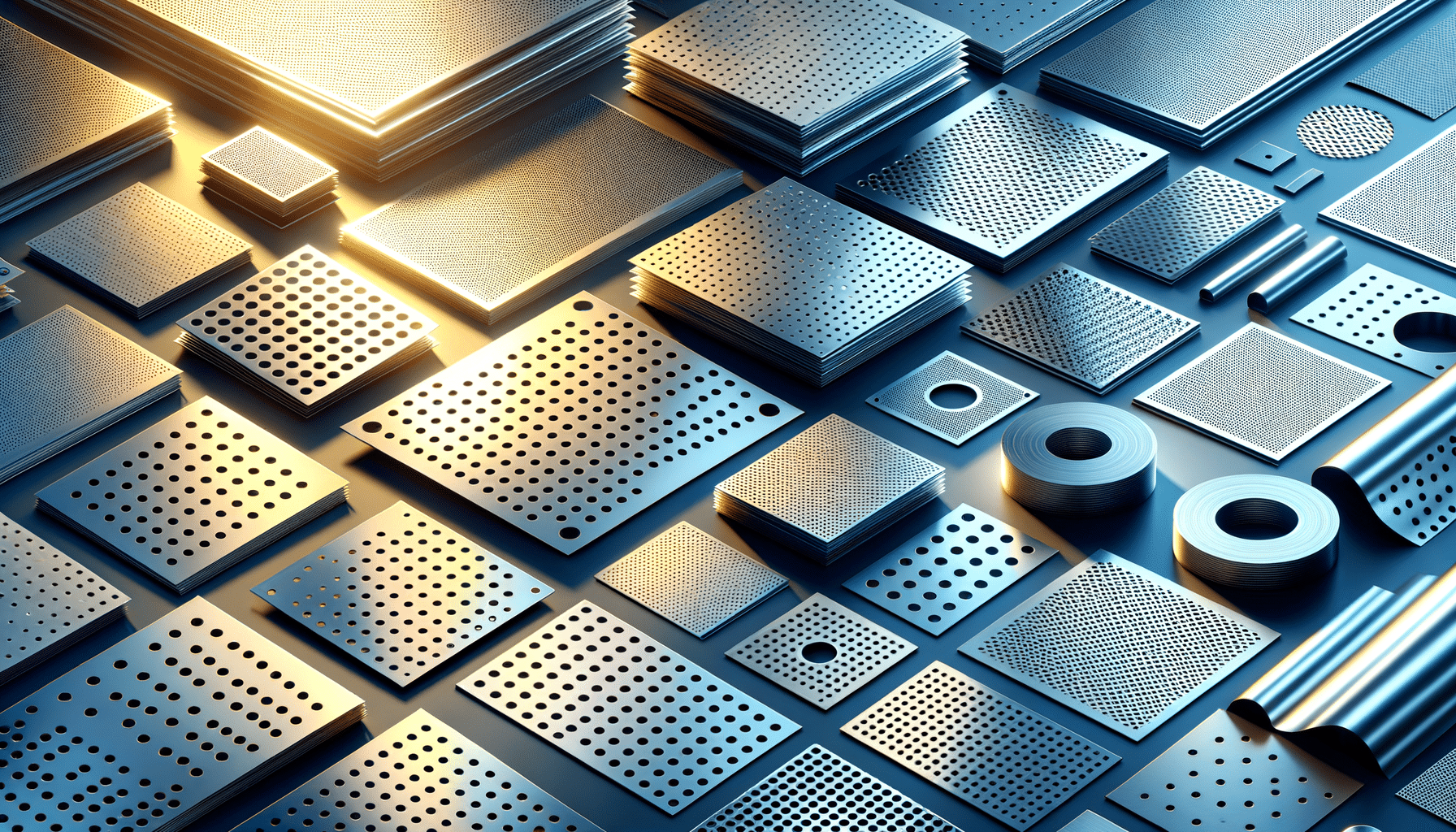

Introduction to Perforated Stainless Steel Sheets

Perforated stainless steel sheets are essential components in various industries, including construction, architecture, and manufacturing. These sheets, characterized by their pattern of holes, offer both aesthetic appeal and functional benefits such as strength, durability, and corrosion resistance. They are used in applications ranging from decorative facades to industrial filtration systems. Understanding the importance of perforated stainless steel sheet suppliers is crucial for businesses and individuals looking to source high-quality materials for their projects.

Key Considerations When Choosing Suppliers

Choosing the right perforated stainless steel sheet supplier involves several critical factors. First, quality assurance is paramount. Suppliers should provide sheets that meet industry standards and specific project requirements. It’s essential to assess the supplier’s manufacturing capabilities to ensure they can deliver sheets with precise dimensions and hole patterns.

Another consideration is the range of products offered. A supplier with a diverse inventory can cater to various needs, from standard sheets to custom designs. Additionally, evaluating the supplier’s reputation through customer reviews and testimonials can provide insights into their reliability and service quality.

Finally, logistical aspects such as delivery times, shipping options, and customer support play a significant role. A supplier who offers timely delivery and responsive support can significantly impact project timelines and overall satisfaction.

Comparing Domestic and International Suppliers

When sourcing perforated stainless steel sheets, businesses often face the choice between domestic and international suppliers. Domestic suppliers generally offer advantages such as shorter delivery times and easier communication. They may also provide better support and flexibility in handling custom orders.

Conversely, international suppliers might offer cost advantages due to lower production costs in certain regions. However, this can come with challenges such as longer shipping times and potential language barriers. It’s crucial to weigh these factors and consider the specific needs of the project when making a decision.

Moreover, understanding trade regulations and tariffs can affect the total cost when dealing with international suppliers. Businesses should conduct thorough research to ensure compliance and avoid unexpected expenses.

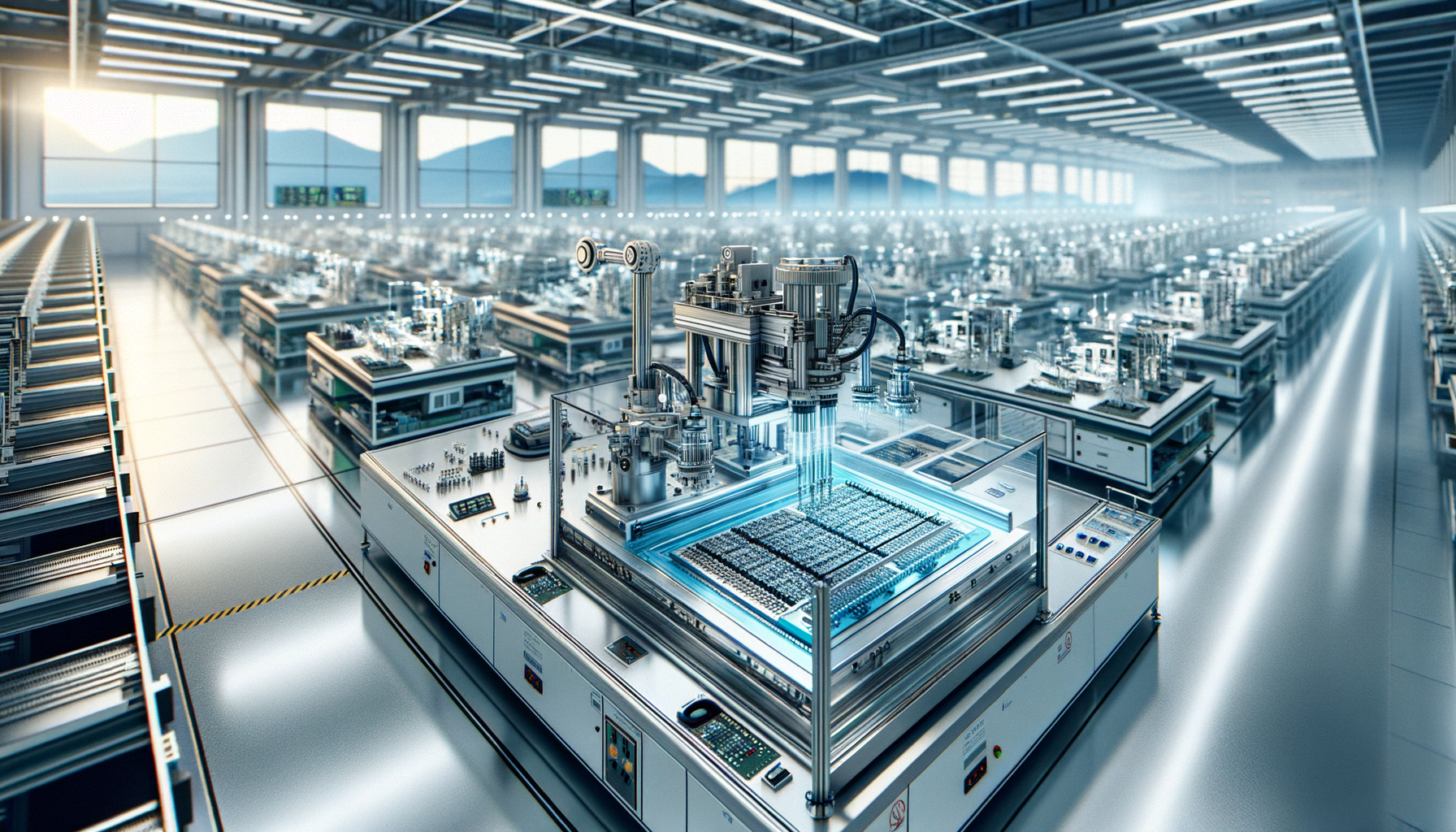

Innovations in Perforated Stainless Steel Sheets

The field of perforated stainless steel sheets is continuously evolving, with innovations enhancing their functionality and aesthetic appeal. Advances in manufacturing technology have enabled the production of sheets with more complex and intricate patterns, expanding their use in creative architectural designs.

Additionally, developments in materials science have led to the creation of sheets with improved properties, such as enhanced corrosion resistance and strength. These innovations allow for broader applications, even in harsh environments.

Suppliers who invest in research and development can offer cutting-edge products that meet modern demands. Staying informed about these innovations can help businesses choose suppliers that align with their forward-thinking goals.

Conclusion: Selecting the Right Supplier

In conclusion, choosing the right perforated stainless steel sheet supplier is a decision that can significantly impact the success of a project. By considering factors such as quality, product range, and supplier reputation, businesses can make informed choices that align with their needs and objectives.

Whether opting for domestic or international suppliers, understanding the trade-offs and benefits is crucial. Keeping abreast of innovations in the industry can also provide a competitive edge. Ultimately, a well-chosen supplier can offer not only high-quality materials but also valuable support and partnership in achieving project goals.