Exploring Gasification and Pyrolysis of Waste: A Sustainable Approach

Introduction to Gasification and Pyrolysis of Waste

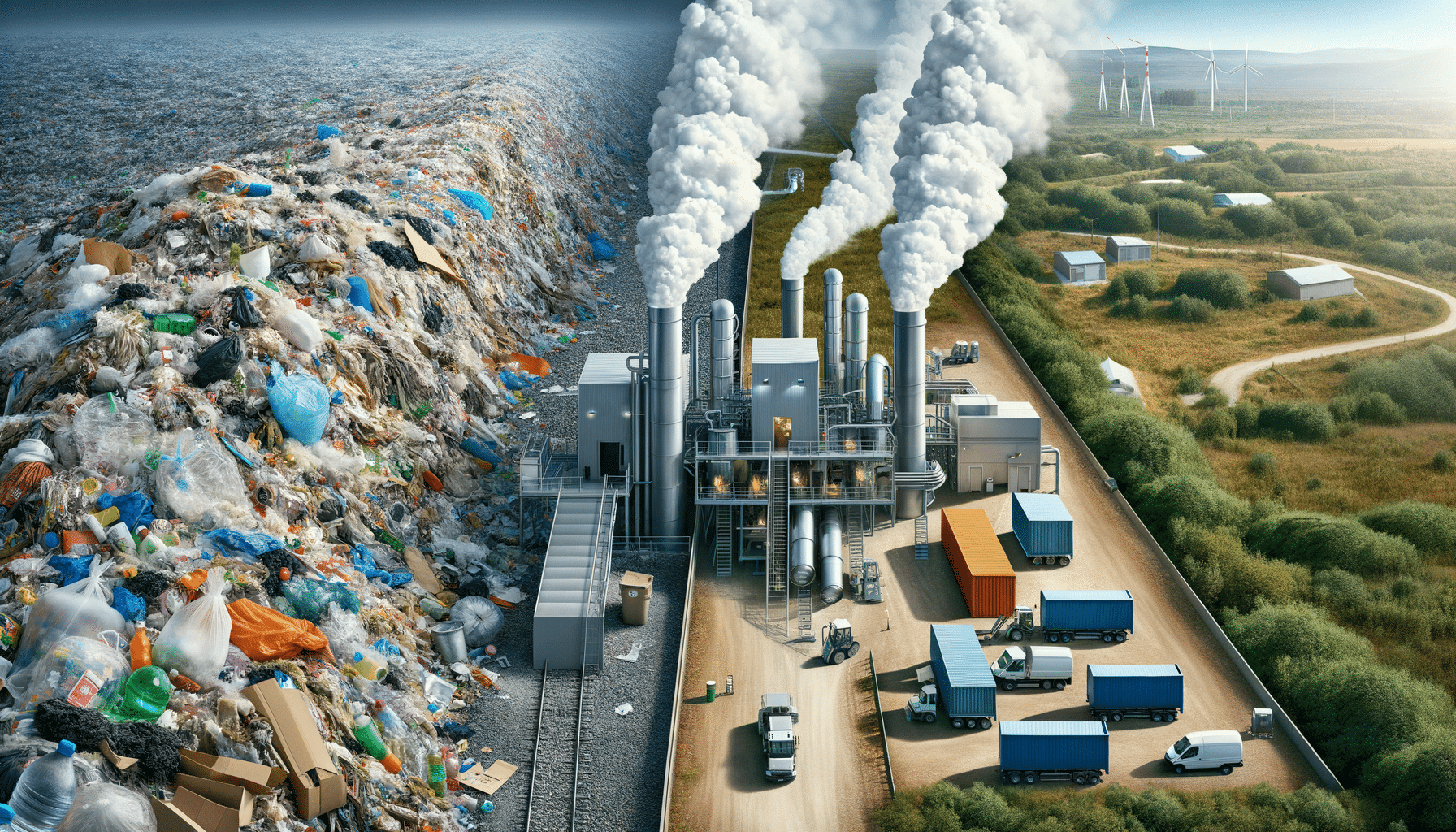

In the quest for sustainable waste management solutions, gasification and pyrolysis have emerged as promising technologies. These methods offer innovative ways to convert waste into valuable resources, reducing the environmental impact of waste disposal. With increasing urbanization and industrialization, the volume of waste generated worldwide is on the rise, making efficient waste management more crucial than ever. Gasification and pyrolysis not only help in managing waste but also contribute to energy recovery, aligning with global sustainability goals.

Understanding the Gasification Process

Gasification is a process that converts organic or fossil-based carbonaceous materials into carbon monoxide, hydrogen, and carbon dioxide. This is achieved by reacting the material at high temperatures (>700°C), without combustion, with a controlled amount of oxygen and/or steam. The resulting gas mixture is known as syngas and can be used for electricity generation, as a chemical feedstock, or for hydrogen production. Gasification offers several advantages:

- Reduces landfill waste by converting it into energy.

- Produces less air pollution compared to traditional incineration.

- Provides a versatile energy product, syngas, which can be used in various applications.

However, the process requires sophisticated technology and significant capital investment, which can be a barrier for widespread adoption.

The Pyrolysis Process Explained

Pyrolysis involves the thermal decomposition of materials at elevated temperatures in an inert atmosphere. Unlike gasification, pyrolysis does not involve oxygen. The process breaks down the material into three primary products: biochar, bio-oil, and syngas. Each of these products has potential uses:

- Biochar: Used as a soil amendment, it enhances soil fertility and sequesters carbon.

- Bio-oil: Can be refined into renewable fuels or used as a chemical feedstock.

- Syngas: Similar to gasification, it can be used for energy production.

Pyrolysis is particularly effective for treating plastic waste and biomass, offering a pathway to convert these materials into valuable resources.

Comparing Gasification and Pyrolysis

Both gasification and pyrolysis offer unique benefits and are suited for different types of waste. Gasification is typically more efficient for high-moisture content waste, such as municipal solid waste, while pyrolysis is often used for dry waste streams like plastics and biomass. Here are some key differences:

- Temperature: Gasification operates at higher temperatures than pyrolysis.

- Oxygen Requirement: Gasification requires a controlled amount of oxygen, while pyrolysis occurs in an oxygen-free environment.

- End Products: Gasification primarily produces syngas, whereas pyrolysis produces biochar, bio-oil, and syngas.

Choosing between these technologies depends on the specific waste stream and the desired end products.

Challenges and Future Prospects

While gasification and pyrolysis present exciting opportunities, they also face challenges. High initial costs, technological complexity, and regulatory hurdles can impede their adoption. Additionally, the quality and consistency of the end products can vary, affecting their marketability. Despite these challenges, ongoing research and development are paving the way for more efficient and cost-effective processes. As technology advances, these methods are expected to play a significant role in the circular economy, turning waste into a resource and reducing reliance on fossil fuels.