Custom Conveyor Solutions for Warehouses in Mexico

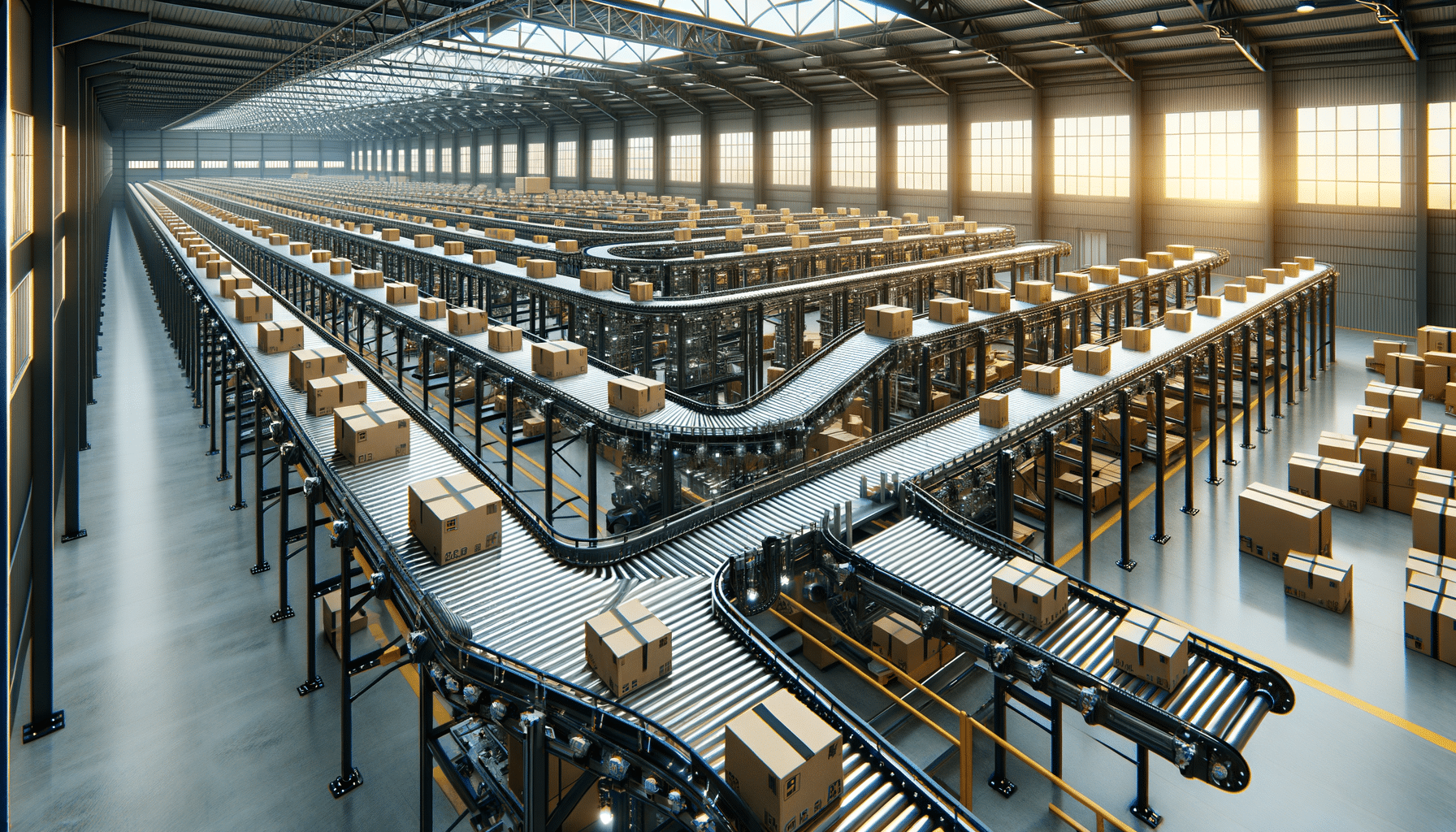

Introduction to Custom Conveyor Solutions

In the dynamic world of logistics and warehousing, efficiency and adaptability are key. Custom conveyor solutions have emerged as a pivotal component in optimizing warehouse operations, particularly in regions like Mexico where industrial growth is rapid. These solutions are tailored to meet specific operational needs, ensuring that businesses can handle increasing demands with ease. By integrating custom conveyors, warehouses can significantly enhance their throughput, reduce manual labor, and improve overall productivity.

The importance of these solutions cannot be overstated. As warehouses strive to meet the challenges of modern supply chains, the ability to customize conveyor systems to suit specific needs offers a competitive edge. This adaptability not only improves efficiency but also minimizes downtime and operational costs, making it a smart investment for any forward-thinking warehouse operation.

Benefits of Custom Conveyor Solutions

Custom conveyor solutions offer a multitude of benefits that standard systems simply cannot match. One of the most significant advantages is the ability to tailor the system to fit the unique layout and operational requirements of a warehouse. This customization includes everything from the size and speed of the conveyors to specialized features like sorting mechanisms and automated controls.

Some key benefits include:

- Enhanced Efficiency: By designing conveyors that align with specific workflows, warehouses can significantly reduce bottlenecks and streamline operations.

- Cost Savings: Custom systems often lead to reduced labor costs and lower energy consumption, contributing to overall savings.

- Scalability: As business needs change, custom conveyors can be adjusted or expanded, offering a long-term solution that grows with the company.

- Safety Improvements: By minimizing manual handling and optimizing processes, custom solutions enhance workplace safety.

These benefits make custom conveyor solutions an attractive option for warehouses looking to improve their operations and remain competitive in the market.

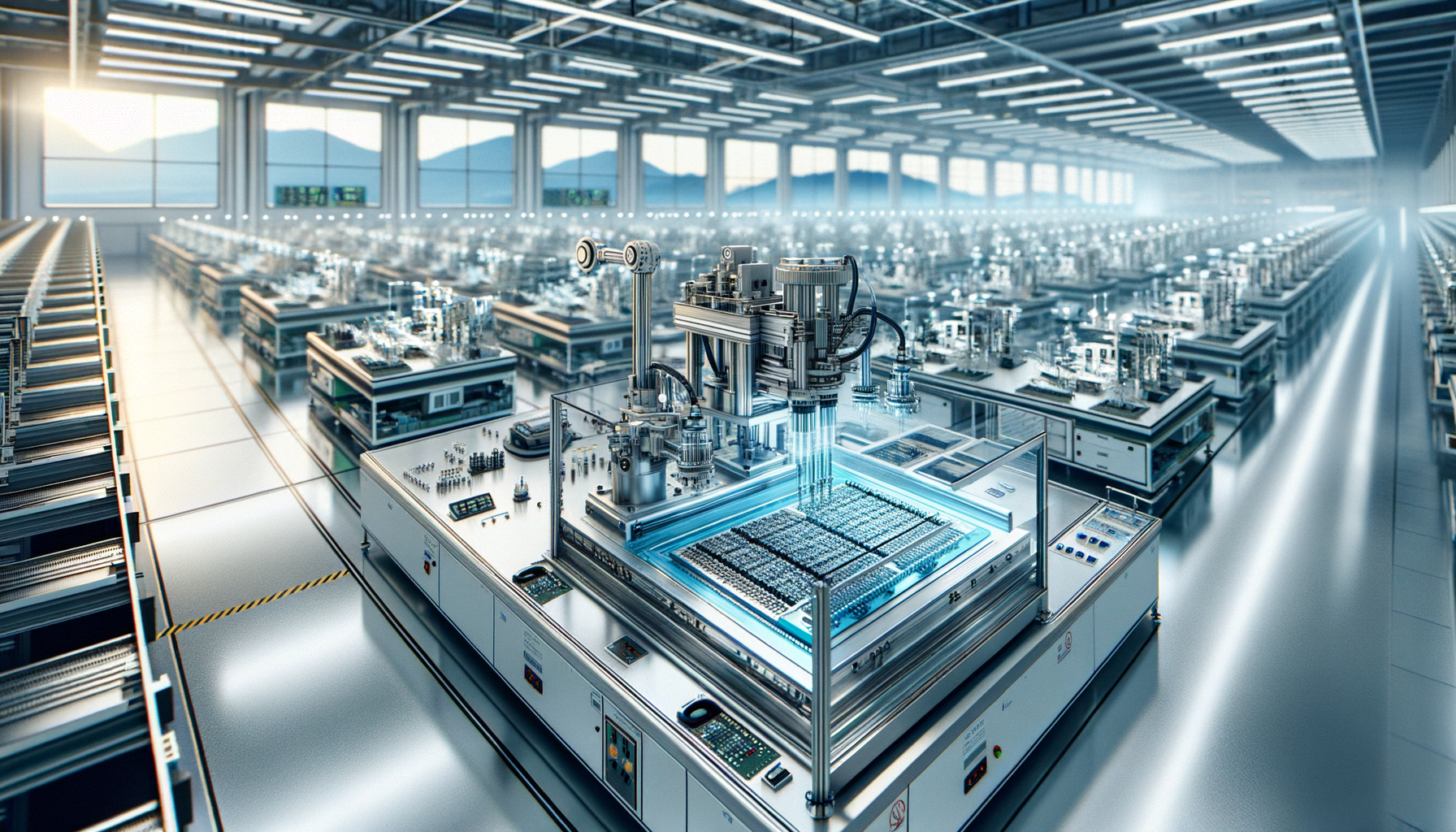

Technological Innovations in Conveyor Systems

The evolution of technology has significantly impacted the design and functionality of conveyor systems. Modern custom conveyor solutions incorporate advanced technologies that enhance performance and reliability. In Mexico, where the warehousing sector is rapidly advancing, these technological innovations are particularly relevant.

Some of the latest technological advancements include:

- Automation: Automated conveyor systems reduce the need for manual intervention, increasing speed and accuracy in material handling.

- IoT Integration: The Internet of Things (IoT) enables real-time monitoring and predictive maintenance, reducing downtime and improving efficiency.

- Robotics: Integrating robotics with conveyor systems allows for complex sorting and handling tasks, enhancing productivity.

- Energy Efficiency: Newer systems are designed to be energy-efficient, reducing operational costs and environmental impact.

These innovations not only improve the functionality of conveyor systems but also align with the global push towards more sustainable and efficient industrial operations.

Case Studies: Successful Implementations in Mexico

Several warehouses in Mexico have successfully implemented custom conveyor solutions, showcasing the tangible benefits these systems offer. One notable example is a large e-commerce fulfillment center that integrated a custom conveyor system to handle increased order volumes during peak seasons.

This implementation resulted in:

- Increased Throughput: The center reported a 30% increase in order processing speed, enabling them to meet customer demands more effectively.

- Improved Accuracy: With automated sorting and handling, the error rate in order fulfillment decreased significantly, enhancing customer satisfaction.

- Reduced Labor Costs: The need for manual sorting and handling was drastically reduced, leading to significant labor cost savings.

These case studies highlight the practical benefits of custom conveyor solutions and demonstrate how they can transform warehouse operations in Mexico.

Conclusion: The Future of Warehousing in Mexico

As the industrial landscape in Mexico continues to evolve, the role of custom conveyor solutions in warehouses becomes increasingly critical. These systems not only address current operational challenges but also position businesses to capitalize on future growth opportunities.

Looking ahead, the integration of advanced technologies and the ability to customize solutions will be key drivers of success in the warehousing sector. By investing in custom conveyor solutions, Mexican warehouses can enhance their efficiency, reduce costs, and improve service delivery, ensuring they remain competitive in a rapidly changing market.

In conclusion, custom conveyor solutions represent a strategic investment for warehouses in Mexico, offering a pathway to enhanced operational efficiency and long-term success.