SCM Robotics: The Future of Intelligent Supply Chain Management

Introduction to SCM Robotics

In the rapidly evolving world of supply chain management, robotics has emerged as a transformative force. As businesses strive to enhance efficiency and reduce costs, the integration of intelligent robotic solutions has become a focal point. This technological advancement is not only reshaping the operational landscape but also paving the way for a more streamlined and intelligent supply chain.

Robotics in supply chain management (SCM) offers numerous benefits, from automating repetitive tasks to optimizing resource allocation. The ability to handle complex logistics with precision and speed makes robotics an invaluable asset in today’s competitive market. This article delves into the various facets of SCM robotics, highlighting its significance and potential for the future.

The Role of Robotics in Enhancing Efficiency

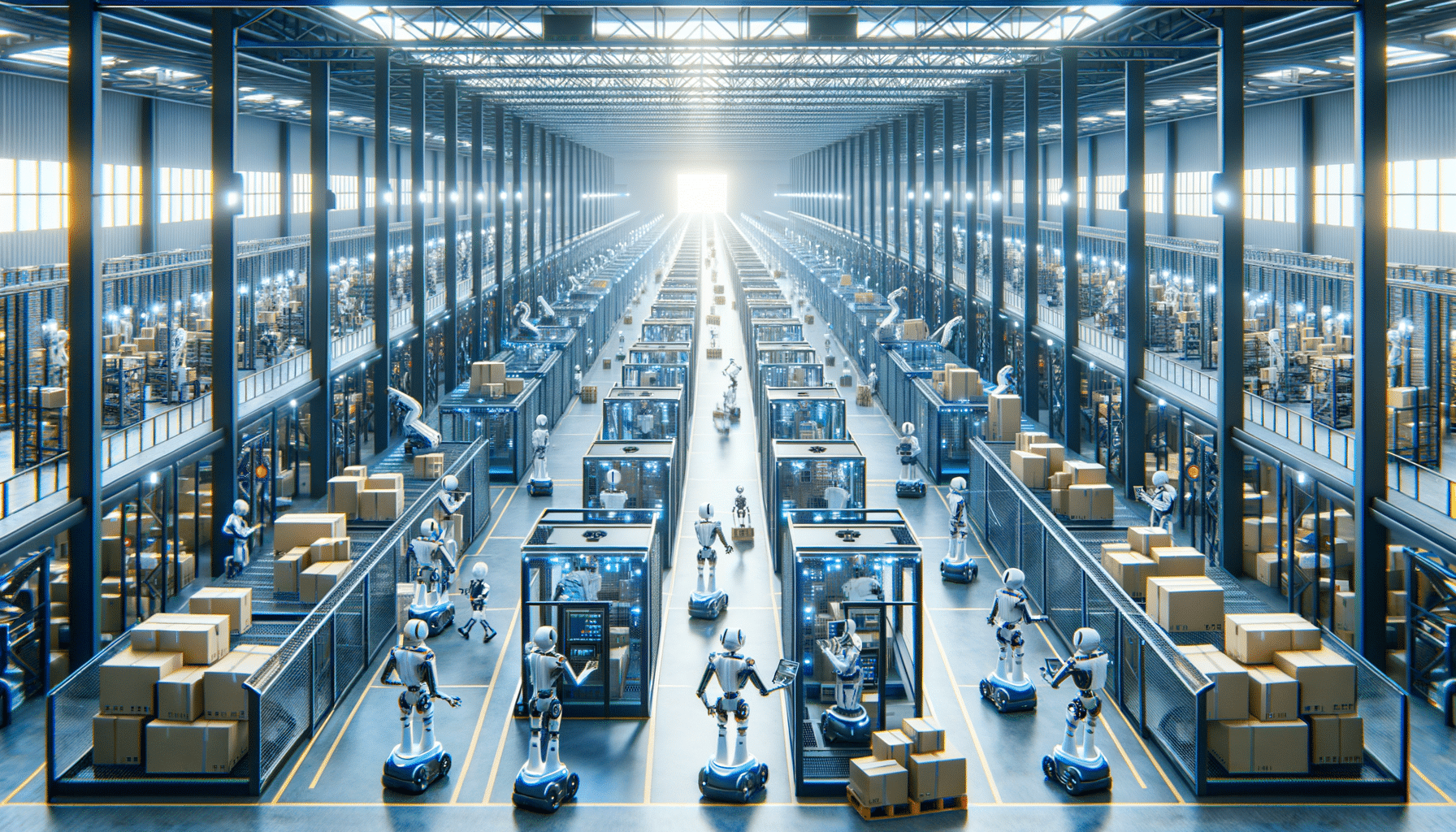

One of the primary advantages of integrating robotics into supply chain management is the significant boost in efficiency. Robots can perform tasks with a level of precision and consistency that is often unattainable through manual labor. This capability is particularly beneficial in warehouse operations where tasks such as sorting, picking, and packing require speed and accuracy.

For instance, automated guided vehicles (AGVs) and robotic arms are increasingly being deployed to streamline warehouse operations. These robots can navigate complex environments, transport goods, and even collaborate with human workers to enhance productivity. By reducing human error and minimizing downtime, companies can achieve higher throughput and improved service levels.

Moreover, robotics technology allows for real-time data collection and analysis, enabling businesses to make informed decisions quickly. This data-driven approach facilitates better inventory management, demand forecasting, and supply chain optimization.

Cost Reduction Through Automation

Implementing robotics in supply chain management also leads to substantial cost savings. Automation reduces the need for manual labor, which in turn lowers labor costs. Additionally, robots can operate around the clock without fatigue, increasing operational hours and maximizing asset utilization.

Cost reduction is further realized through decreased error rates and waste. Robots execute tasks with high precision, minimizing the likelihood of mistakes that can lead to costly rectifications. Furthermore, the efficient use of resources and energy by robotic systems contributes to overall cost efficiency.

Companies that have embraced robotics in their supply chains often report a significant return on investment. The initial costs of deploying robotic systems are quickly offset by the long-term savings and enhanced operational capabilities.

Innovations and Future Trends

The field of SCM robotics is continuously evolving, with new innovations and trends emerging regularly. One notable trend is the development of collaborative robots, or cobots, designed to work alongside humans. These robots enhance human capabilities by taking over strenuous tasks, allowing workers to focus on more strategic activities.

Another exciting development is the use of artificial intelligence (AI) in robotics. AI-powered robots can learn from their environment and adapt to changing conditions, making them highly versatile and efficient. This adaptability is crucial in dynamic supply chain environments where flexibility is key.

Looking ahead, the integration of Internet of Things (IoT) technology with robotics is expected to drive further advancements. IoT-enabled robots can communicate with other devices and systems, creating a connected ecosystem that enhances visibility and control over the supply chain.

Conclusion: The Future of Intelligent Supply Chains

As robotics technology continues to advance, its impact on supply chain management will only grow. The future of SCM lies in intelligent systems that leverage robotics, AI, and IoT to create more responsive, efficient, and resilient supply chains.

Businesses that embrace these technologies stand to gain a competitive edge by improving their operational efficiency, reducing costs, and enhancing customer satisfaction. As we move forward, the role of robotics in supply chain management will be pivotal in shaping the future of global commerce.